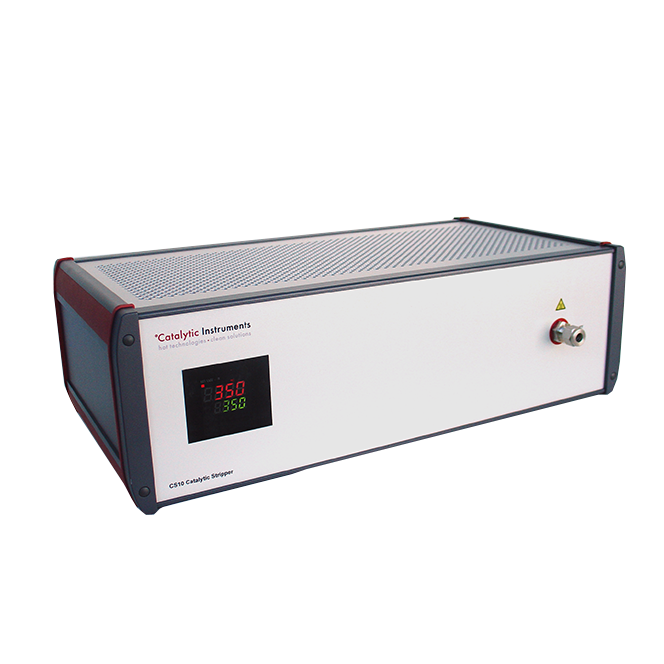

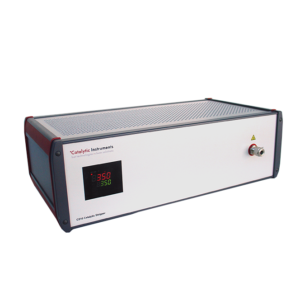

А catalytic stripper is a heated catalytic element used to remove the particle and gas-phase semi-volatile fraction of an aerosol.

Diesel, locomotive, and gas turbine exhaust contain a complex mixture of solid particles and semi-volatile material that is found in both the particle and the vapor phase. Physical and chemical characterization of these exhaust aerosols in the environment enables a better understanding of potential health effects, effectiveness of alternative combustion technologies and emission control devices, and the impact of new fuel and lubricant formulations on emissions. These measurements are enabled through the use of catalytic stripper (CS) technology.

Features and benefits

- Robust measurement of solid material without re-nucleation artifacts

- High hydrocarbon oxidation efficiency

- Portable and easy-to-use

- No consumable parts

- Remote data logging option via USB-Interface (MODbus communication)

Applications

- Diesel exhaust measurements

- Gas turbine non-volatile particulate matter

- Solid particle concentration in ambient air